“It’s about Respect for the Material.”

Kai Strehlke (Blumer-Lehmann AG) in Conversation with Urs Hirschberg (GAM)For the past five years, the architect Kai Strehlke has been in charge of digital processes in CAD/CAM production for the Swiss timber construction company Blumer-Lehmann. Before that, he worked as head of IT for ten years at the architectural firm Herzog & de Meuron. At Herzog & de Meuron, he worked on many of the firm’s internationally famous projects. He is familiar with the practice of architecture and not just from the perspective of timber construction that has since become his specialty. Blumer-Lehmann is a family business in eastern Switzerland with a rich tradition. The Erlenhof, where its first sawmill was founded in 1875, and where, together with a second site nearby, the entire production takes place, is an idyllic rural location near Gossau (fig. 2). For contemporary architecture in wood, especially in the area of freeform geometries, Blumer Lehmann is a prime address with an international profile. In the recent past, Kai Strehlke has been a crucial collaborator on projects such as the new Swatch headquarters (architecture: Shigeru Ban Architects, Paris/Tokyo) and the mosque in Cambridge (architecture: Marks Barfield Architects, London). Most of the illustrations that follow are from these two projects. This interview with Kai Strehlke, who, before being hired by Blumer Lehmann, taught for a semester in 2015 as a visiting professor at Graz University of Technology, was conducted via video conference in September 2020.

GAM: You’ve been working at Blumer Lehmann, a family-owned company, for five years. In view of the long time you spent at one of the leading international architecture firms, it is perhaps surprising that you ended up at a timber construction company in a rural area. But at Blumer-Lehmann you can also work on extremely exciting projects that are then built worldwide. The company pulls off the trick of remaining internationally competitive as a production operation in the high-wage country of Switzerland. You manufacture construction parts in expensive Switzerland and ship them to England, even to the timber country Norway, indeed, even to Korea which is far away and famous for considerably lower wage costs. How does that work? What makes Blumer Lehmann so much better than the local competition in those countries?

KS: The company has a long history. It was founded as a sawmill in 1875. We have a long tradition of timber construction and have enormous knowledge about wood as a material. We in the company attach great importance to upskilling our workers and teaching apprentices and students from technical colleges about wood’s potential today and in the future. Moreover, we are well networked with universities such as Stuttgart, the EPFL Lausanne, the ETH Zurich, and the EMPA (Swiss Federal Laboratories for Materials Science and Technology). We have many projects from which we are learning what wood fibers could do in the future. Looking at the past, on the one hand, and being open to the future, on the other, distinguishes this company. But to return to your question: We are competitive abroad, above all with our freeform constructions, because we are a step ahead of our competitors in terms of know-how. Our main market, however, is still Switzerland.

GAM: You mention your research focus. Is that the secret? In many sectors, production has long since moved to China. Do you manage to compensate for the personnel costs in production in Switzerland with better know-how in engineering?

KS: Dedication to research is important. It’s important to network with powerful research partners and to do your own research in house. The projects we sell abroad are usually lighthouse projects. Other companies are often not even in a position to build them. There are only a few that can. Blumer Lehmann has the competence to do that, not necessarily because we have “extreme specialists,” but because we are set up internally very well as a team and have a lot of specialized knowledge: carpenters, structural engineers, timber-construction engineers—people who are in a position to master the complex logistics and also people like me who understand digital processes very well. It’s thanks to this team that complex designs can be built. What makes us distinctive is the team.

Another reason we are successful is Katharina Lehmann, our CEO; she is bold about taking the entrepreneurial steps, even though they are often tied to relatively large risk. She takes on projects in which, perhaps, no one knows at the start how they will be completed. But she has faith in her team, that it will be able to find solutions. That is why we stand out as a company.

These international projects can also be regarded critically. It isn’t especially sustainable to prepare the wood in Switzerland and transport it by truck to the United Kingdom or by ship to Korea to assemble it there. But I believe that these projects, these lighthouse projects, provide an unbelievably good service to timber construction. They advance timber construction in other countries as well. The United Kingdom in particular is a very brick-heavy country. A project like the mosque in Cambridge has a signal effect there. Even in Switzerland, wood construction has regained importance only recently, especially in residential architecture. These lighthouse projects are helping the material achieve a boom again.

GAM: These lighthouse projects have a lot to do with digital manufacturing, in which you have specialized. A lot is happening right now with digitalization and robotics in the construction business. At the same time, there is a strong trend toward wood as a sustainable building material. As a company, you surely profit from woodworking and digitalization going together so well. Timber construction has lots of potential for prefabrication. You can accelerate construction processes that way. How do you see the general evolution toward timber construction in terms of digitalization and also in connection with the theme of sustainability?

KS: You are talking about two themes: sustainability and digitalization. Sustainability is a highly topical subject right now, if you consider movements such as Fridays for Future and the general CO2 debate, which is a big political issue right now, or at least will be again after the pandemic. Wood is a material that plays an important role in this debate. Wood absorbs CO2; concrete uses CO2. Wood can provide an answer to the discussion of sustainability in the construction business. Famously, the construction business is responsible for 35 to 40 percent of CO2 emissions. That wood makes so much sense as a material in terms of the CO2 balance naturally benefits timber construction.

There are two big trends in digitalization: prefabrication and building in situ, that is, building on the construction site. Concrete is also used in prefabrication, but lots of concrete and stone are built on site. Wood has a long tradition in prefabrication. German timber-framed buildings were preassembled on locations outside of the villages. That was a logistical solution so that the parts could be brought into the village and reassembled there. Those were inventions made already hundreds of years ago that have always given wood an advantage in prefabrication. Digitalization is merely a logical further development of these practices using today’s technological possibilities. Wood has great advantages here. The primary reason people turned away from wood for such a long time was that wood can burn. Many villages and towns had been almost or totally destroyed by fires in wooden buildings. Today, we have a handle on fire safety. That means it makes sense again to bring wood into cities.

Prefabrication is an enormous advantage for construction sites in the city: Very complicated parts can be prefabricated outside of the city and then assembled, Lego-like, in the city. You have short construction times and small construction sites. Wood is perfectly suited to prefabrication. Moreover, it is not as heavy as stone or concrete. Cities are growing; we need more and more residential space. We can not only build new buildings; with a light material like wood, we can also add new floors and add to existing buildings. Wood makes sense as a material for that. I believe that wood is the material for our time.

What I am experiencing at the moment is a kind of pioneering attitude in timber construction, which seems to me similar to that of Mies van der Rohe in Berlin or of the United States in the 1920s. I have the feeling that wood is as interesting at the moment as glass and steel were then. It is interesting that it is an ancient material that we are in the process of rediscovering.

GAM: Don’t the reasons for this rediscovery also lie in a different appreciation of wood as a material?

KS: I don’t know whether it oversimplifies the matter, but this is how I see it: In the course of industrialization in the 1950s, 1960s, and 1970s, there was an effort to work in standardized ways. For that reason, people wanted to have homogeneous materials in factories. The culmination of this development was that wood—or rather what distinguishes wood as a material, namely, fibers, the anisotropic qualities of wood were completely destroyed by grinding it up and gluing it back together. That is truly a mutilation of wood. The resulting material is called MDF: a homogeneous material that has the same properties in all directions. But they are the same bad properties, because the fibers that make wood so incredibly strong have been destroyed in the process. Now people are recognizing that it is better not to work against the fibers but with them.

© Blumer-Lehmann AG

GAM: The theme of this issue is “Rethinking Material.” You have just shown that rethinking can also mean learning to recognize and appreciate the things that earlier generations already knew. You mention the postwar period. This dumbing down of the material wood, that is, into fiberboards, was also done because it made everything simpler. You didn’t have to think as much; it was much easier to calculate everything. Everything gets more complicated when you take the construction material just as it grew, but it also provides other opportunities. Let’s talk about these opportunities now. At Blumer-Lehmann, you are willing to try out new things, and you also emphasize that you like to work together with the architects from as early on as possible, so your expert knowledge can contribute to the design. Does that happen? Is it always the case that architects come to you early when they are developing a project that treats wood in a virtuosic way?

KS: I would say that when highly complex projects are successful, that was how it happened. There are, of course, various work phases that are regulated a little differently depending on the country, but in both Germany and Switzerland the companies implementing the project come into play only after the call for bids. The architects develop the project first with specialized planners, etc. The companies get involved only thereafter.

What we are advocating and doing very successfully, especially in private freeform projects, is that we build a pilot, a mockup, before the call for bids (figs. 9–10). In such a mockup, we test the production and the aesthetic, and we also see what drives up the costs in the project, and how they can perhaps be reduced, for example, by reducing curvatures or making slight changes to the architecture. It’s not about changing the architecture. It’s about determining a design’s consequences for its realization. With private projects, that’s very successful. For public tenders, the problem is that we as a company can only come into play after the contract is awarded. That often leads to projects that are incredibly difficult to implement. Then the projects also become substantially more expensive.

GAM: That means that the guidelines for public contracts really have to be changed. The mockup would have to be part of the preliminary planning phase. You’re saying that the guidelines get in the way of a rational approach that could also reduce costs?

KS: Yes!

GAM: That means that you’re in fact at a disadvantage when it comes to public tenders with your approach to projects?

KS: I don’t believe we’re at a disadvantage. It’s often the case, after all, that the companies that make cheap bids without really assessing the construction then take on more than they can handle. You saw that a lot with the blobs, the freeform architecture, that emerged in the late 1990s. They took the lowest bidder, who was then not able to implement the project. When a company goes bankrupt, and sometimes even a second company goes bankrupt, that certainly does not reduce costs. On the contrary, costs increase. In such cases, it would have been better to take someone who had seriously estimated the costs from the outset.

Especially with free forms, that is, with more complex architectural tasks, that’s the biggest problem with the current stages of contract, in my view. I would absolutely argue for introducing an additional phase, a mockup phase, that occurs before the construction bid, when the architect is still in the design stage, so his or her knowledge and the company’s knowledge can be incorporated into the project.

GAM: The mockup as key, very interesting. That reminds me of an anecdote that Peter Cook told me about the building of the Kunsthaus Graz. The full-scale mockup of the façade that was built at the time and shown at the Venice Architecture Biennale also played a key role in its building …

KS: People often try to skip the mockup, but that’s precisely the wrong approach! It is the first opportunity for architects to experience in practice, physically, what they are designing. That’s an incredibly beautiful moment, not only for the architects but also for the client, because for the first time they sense what they will get. A second thing we have learned is that mockups accelerate the decision-making processes, because issues can be clarified in a more grounded way. In the end, you even save time.

© Blumer-Lehmann AG

GAM: Presumably, when it comes to the architectural firms with which you work often, you don’t have to work to convince them. With Shigeru Ban, for example, you have already done a whole series of projects. I assume that mockups play an important role there. How does your collaboration with Shigeru Ban’s office work?

KS: We have done projects not only with Shigeru Ban but also many with Norman Foster. These firms come to us very early in the development of their projects. We don’t just do one mockup when the design is more or less finished. No, these offices come early in order to test what is possible with wood and how far they can go with it to realize their architecture. Their clients understand the importance of these mockups as part of the design process and in clarifying technical possibilities in detail. Often, we try out new technologies with these firms.

GAM: That was clearly true of the new main headquarters for Swatch in Biel, which you developed with Shigeru Ban. The project is one of the largest, also in terms of sheer size, that you have ever realized. I think it was 2015 when we visited you with a group of students. Already at that time you showed us an impressive mockup from the Swatch project. So that project was in preparation for a very long time. It was completed in 2019. What were the biggest challenges of that project? Were you involved in the project from the beginning?

KS: I was involved in production from the beginning. I started in 2015, and I believe it was the autumn/winter of 2015 when we were awarded the contract to build the project.

GAM: But there was already a mockup.

KS: There was already a mockup. These freeform projects usually have a relatively long run-up time. I don’t remember exactly how many years it took before production started. I joined this project when production was starting. It was clear that we at Blumer-Lehmann could not manage it alone. We worked on that project as an alliance of five different timber construction companies. Timber construction companies in Germany, in France, and in Switzerland worked to manufacture a total of 4,600 parts on schedule. Organizing that was a novelty and hence also a challenge. Because of the geographical distances, it was not possible to test assembly ahead of time. The parts all went directly to the construction site and had to fit down to the millimeter.

GAM: Who coordinated the whole thing?

KS: We were holding the reins, but it was a collaboration between SJB Kempter Fitze AG as the structural engineers, the firm Design-to-Production, which prepared the data and us. We were responsible for the overall project planning, the organization, and the risk. Design-to-Production prepared the data for the various wood manufacturers in accordance with the requirements of their production facilities. We got the data in Rhino format, that is, as pure geometric data, and based on that geometric data we wrote, programmed, and scripted all of the code to control our machines.

© Blumer-Lehmann AG

There were various challenges. One challenge was the alliance of different companies. Another was the construction itself. In timber construction, one distinguishes between frames and panels and beams. With the building in Biel, we have nothing but curved beams. That means that the existing industrial processes for cutting and milling panels and straight beams do not work. We had to develop completely new processes for this building. That was a risk, of course. The time factor is crucial. When we calculate a construction part with time X and have a certain buffer, there is always a little speculation involved. It may be that we have not considered something, and it takes three or four times longer to produce that construction part. We were working twenty-four hours daily without a break for more than a year. Our milling machines never stopped. If we had misjudged, the project could have taken one, two, or even three years longer. That is, of course, a great challenge; not to misjudge is a high art.

The processes—that is, these different wood joints we developed for the project—were completely new. In the beginning, it took about forty-five minutes to mill them. During the project we were able to reduce these processes to three to five minutes. If you scale that up, you see what a challenge it is to calculate such a project in a way that it can be produced on schedule.

GAM: It’s easy to underestimate this time factor. We also experience that in our full-scale projects that we build with students. But with a project as enormous as the Swatch headquarters, you are in an entirely different dimension, of course.

KS: About that, quickly: If you look at the Olympic stadium by Herzog & de Meuron in Beijing, the “Bird’s Nest,” that had a strict time plan, too, of course. But in that case we could simply increase the number of workers on the construction site. So there were thousands of workers on the construction site. That works with many architectural projects: you can speed things up simply by having more people. We couldn’t do that because we had to mill these things on our machine.

GAM: But you could build a second or even a third factory next to it and work in parallel, when money plays no role.

KS: But that doesn’t work within the time frame. When people are installing windows on a construction site, it’s easy to organize another twenty window installers from one day to the next, who can then help you speed up construction. But you can’t build a factory in two weeks. And the machines we use to mill are not mass produced either. You can’t get them in that time frame. That is why the time factor is associated with so much risk in our projects. And money always plays a role, since in the end every single one of our projects has to work in terms of economics as well.

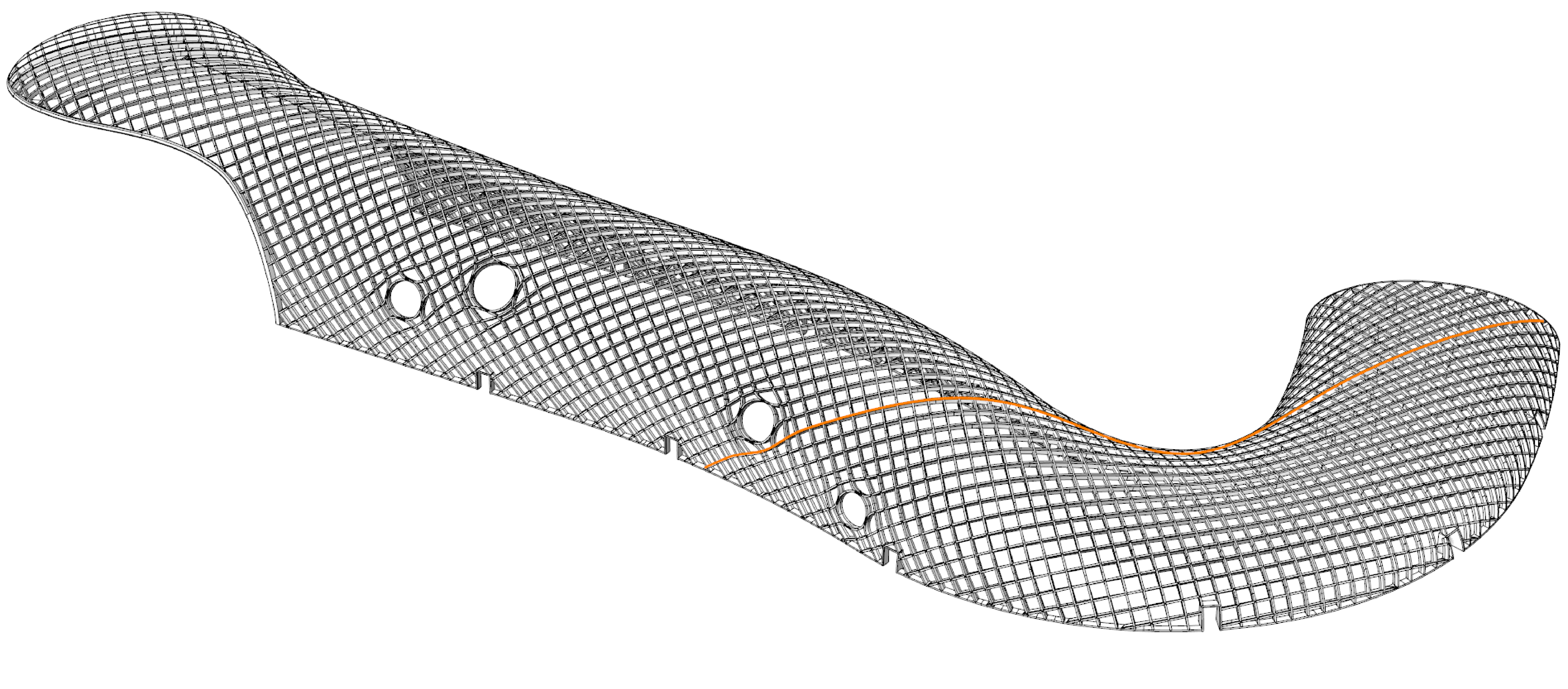

GAM: Let’s return to the unusual characteristics of construction in the Swatch project. You’ve already mentioned that wood is an anisotropic material. For the doubly curved beams, which are then no longer beams, that is, of course, highly relevant. They should be stressed in the direction of the grain as much as possible. Can you explain how this doubly curved fiber direction was achieved in the Swatch project?

KS: It can be explained mostly simply with the aid of pictures. In figure 13 you see that wood has very good properties when compressive or tensile stress runs along the grain. Its properties under compression and tension get worse when deviating from this direction—up to about five degrees, it’s still OK. At right angles to the grain, its properties are extremely poor.

GAM: So up to five degrees is still OK?

KS: Yes, that’s still OK. That is relatively slight. That means that when milling a construction part you have to be very certain that the path of forces always moves along the grain. We talk about the fiber-cutting angle. In figure 11 you see the production of a single-curved glue laminated beam. Theoretically, you could also mill it out of a single, enormous piece of wood. But the structural properties would then be very bad, because the forces would no longer run along the grain. The solution is to cut the wood into single boards, curve them, and glue them in a curved state. For single-curved beams, that is very efficient; you can make them entirely by machine.

For double-curved beams, however, it is much more complicated (fig. 12). You can only bend a board in one direction, after all. For that reason, the whole procedure has to be done twice. When the single-curved beam is finished, it is cut in the other direction into boards and glued together in this second direction. You can imagine how much more complicated it is to get this wood really into the right form. If you look at the illustration more closely, you will see that they are no longer normal boards. They are curved boards that were curved a second time here. The idea is always the same. You try to get the wood so that the lines of force follow the grain. When I bend wood, it tries to bend back elastically. That means that when I bend the wood and glue it together, then I have a state that is stable. But every one of these lamellae is under tension. It is a whole construction part in which there are an incredibly large number of tensions.

© Morley von Sternberg

GAM: These single- or double-curved beams, however, are just the “raw parts” from which the beams are ultimately precisely milled. Were these raw parts for the Swatch project also manufactured by the various timber-construction companies?

KS: For Swatch, we worked with the firm Hess; they did it differently. What I just showed you was bending the laminations in one direction then cutting them up like a salami and bending them in the other direction.

GAM: The “salami principle.” But there is also the “spaghetti principle” …

KS: Precisely. The Hess firm worked using the “spaghetti principle.” Rather than boards, they simply used “sticks.” The sticks were bundled and placed into a form and glued. That skipped one of the two procedures.

GAM: And Hess did that for the other companies as well?

KS: Exactly!

GAM: Then you only have to do the finishing work, so to speak?

KS: Yes. Naturally, you try to be as economical with the material as possible. The ideal would be not milling anything off at all in the longitudinal processing, but with all the glue it’s not possible. Nor do we manage to achieve the curvature perfectly. Even with these spaghetti beams, there are springback forces, that is to say: the wood tries to become straight again. That cannot always be predicted perfectly. Usually, we leave an excess of two centimeters in this longitudinal processing, and then we mill off these two centimeters. That results in yet another difficulty. Now it may be that when milling I end up precisely at the transition between two lamellae. It may be that the cut level alternates every three centimeters from the upper lamella to the lower lamella and then back to the upper one. That looks very problematic aesthetically. So during the longitudinal processing we try as much as possible to remain within one lamella or within one layer, which also results in aesthetically beautiful grain patterns. That’s easier if the individual layers are thicker, but you can’t always have that. In figure 14 you see how thick the laminations have to be in relation to the curving. There are different benchmarks, but usually we speak of a ratio of 1:200 between lamella thickness and the smallest curvature radius in the beam. If I have a radius of two meters, that gives a lamella thickness of one centimeter. Glulam beams normally have laminations 40 millimeters thick. Those are the cheapest to produce. Thus, a curvature radius of eight meters is economically optimal.

Curving wood has a considerable effect on costs. If I have a price X for straight wood, a single-curved beam will, as a rule, be two to five times more expensive. With a sharper curve, I need thinner laminations, and then single-curved beams become even more expensive. Double-curved wood can cost up to fifteen times as much (fig. 15). We try to segment a building to produce as much as possible with a curvature radius of eight meters in order to use less of the very expensive wood.

Figures 9 and 10 show a mockup we built for the Cambridge mosque (fig. 8). In the lower area, we used single-curved glulam beams, which reach up into the crown. Up above, we had to use double-curved glulam beams, for which we also alternated the lamination thickness. We made this mockup to check whether one sees the alternations in the direction of lamination or from one wood to another. If you look closely, you see it, of course, but it works anyway.

© Blumer-Lehmann AG

GAM: That means there is an optimization task in which aesthetics always plays a role. It is, after all, more beautiful to have the thicker cross sections—simply visually. The thinner the “spaghetti,” the further one is from the “look” one associates with timber. Ultimately, it’s almost like fiberboard, except that the correct fiber orientation has been preserved. All of that is really very impressive and exciting, also as an optimization task. But faced with this enormous effort, one has to ask if it’s really worth it. Couldn’t a structure of a more homogenous material, such as steel, be produced in a way that is simpler and finally, perhaps, truer to the material?

KS: For the mosque, in the end we managed relatively thin and elegant beams. That means we truly manage to work with the fibers and to activate them in a way that uses wood optimally in building. These free forms are lighthouse projects. The goal for these projects is not to produce the most affordable project possible. Every society needs lighthouse projects; every country, every city, needs its small lighthouse projects. No city in Europe wants to have only banal cookie-cutter architecture. We need something more for tourism; we need it for self-confidence and for the identity of cities. I believe that is a central task of architecture.

What we are doing with wood today is at the forefront of technology. It shows what is possible with wood. It is not just simply about building cheaply with wood, about using wood because it is the cheaper construction material. It is about using wood because it is a better construction material.

GAM: You speak of the mosque in Cambridge in relation to the load-bearing structure of trees. And that is truly a nice analogy. Nevertheless, it is also in a sense absurd that industrial timber production first sorts out all of the curvy parts. Trees that do not grow straight are useless. And then, in a number of logistically complex steps of high-tech processing you make something from all these straight parts that is elegantly and multiply curved and that reminds us of the form of a tree that has grown naturally. Wouldn’t it be even more elegant if from the outset you could use naturally grown curved parts?

© Blumer-Lehmann AG

KS: In our preliminary conversations, you made the analogy to the violin. A violin is an enormous refinement of the wood itself. You go into a forest, search for exactly the tree you want to have for your violin, let the wood dry for years, during which all sorts of tension cracks might result, and then finally you build a violin from it, as the ultimate step of refinement. This violin can in no way be compared to a plastic violin you buy in the supermarket. There are worlds between them. It is about respect for the material. I would claim this respect for our work as well. In my eyes, in our work the respect for the material lies in how we deal with the fibers. For me, it is an enormous difference whether I activate the fibers or whether I don’t activate the fibers.

It is, of course, also a question of perspective. If my perspective is that the wood should, as much as possible, be used as it comes from the forest, without foreign materials, without glue, and so on, then you will get a different architecture. But then you won’t necessarily get a violin either. I don’t want to set one against the other. There is frame joinery, high-rises of CLT (Cross-Laminated Timber), modular construction, normal timber construction, and free form. Wood is diverse; it permits many approaches, and the point is not to say that one approach is the right one and the other wrong. Rather, the point is that the material can be used in diverse ways. It is just as acceptable to build a mosque in Cambridge with curved beams in which this technology is explored, as it is to build with moon wood, which is from trees that are only felled at certain times, and where only wooden nails are used for joints. Take CLT, for example: now people are building high-rises with it. There are designs for building as tall as 300 meters. The question for me is not whether it makes sense to build in wood up to 300 meters. Trying out how far we can go, what is possible, that is something very human. That these spearhead projects are being built, that someone builds a little higher than someone else, that is simply part of the world of architecture.

© Blumer-Lehmann AG

GAM: To what extent do these spearhead projects, as you call them, have the potential to end up in the mainstream at some point? When it comes to IT, we find it normal that we carry around in our pockets devices that would have been supercomputers just a few decades ago. Do you believe that something similar could happen in wood architecture? Will people someday have gazebos in the garden that are made of doubly curved and milled timber parts that they bought at a home improvement store? Or do you believe that that won’t happen in this sector?

KS: I believe these will continue to be niche projects and special projects and tasks. When I look at normal housing construction now, where can I employ free form? I can’t use it for the floor; it’s usually not practical for walls, and most of the freeform projects we have, whether for Swatch or the mosque, are dome buildings and complex roof constructions. We worked on a villa in Turkey for Norman Foster in which we built a roof with a floating geometry over a relatively rectangular floor plan.

As I said, I believe these projects will for the most part truly remain lighthouse projects. But it may be that increasingly there are more smaller lighthouse projects as well. For the cultural center in Böttstein, we recently built a barrel roof for the community hall, and that is a relatively inexpensive free form (fig. 16). We worked without a mockup on that project. It is a barrel roof, though its construction resembles a Zollinger roof. It looks like wickerwork, but in reality, the beams extend to the roof ridge only in one direction. In the other direction, we have small beams that are simply placed between them. We only had to program two parts and then produce them in large quantities.

GAM: What was it like working with the architects in that case? Can you bring your own design ideas into it? Could you describe that briefly?

KS: I can’t describe it, because I wasn’t involved in the design of that one. At Herzog & de Meuron, I worked for ten years in the early design phases, but now I am involved in the very last design phase, as it were. I am only integrated at the very beginning of the design if there is a question about whether something is technically possible at all. That is, when the question is: Will we be able to mill this?

© Blumer-Lehmann AG

GAM: Do you miss being involved in conceptual design?

KS: No, not necessarily. Sometimes, it is a very long ordeal for architects before a project is really underway. Even at Herzog & de Meuron, there were projects that took many years before they were actually realized, before they made it to the construction phase. Now, the projects that land on my desk are under enormous pressure in terms of costs and time, but a few months later they are gone. There are always new projects. I believe that the time I have now is more stressful but also more exciting. It is an enormous satisfaction to see our work leaving the factory. When you know that, now, sixty trucks are leaving for England. When you see these enormous parts on the highway and know they are going to Rotterdam, to Korea, or somewhere else. That is still an incredibly fascinating moment for me. At Herzog & de Meuron many years ago, I was talking to Pierre de Meuron about where I wanted to go with architecture in my life. I said I see three areas: the area of architectural design; I see the area of the academy, of education, and this area of production. It actually bothered me that in the architectural firm I could never get to see the production. That was a logical step for me, to get out of the office and into production. I had the good fortune to arrive at Blumer Lehmann right at the point when these projects were in a hot phase. That was a very exciting moment for me.

GAM: Let’s get back to talking more generally about the future of timber construction. You said at the beginning that building with wood is currently experiencing a heyday, comparable to the beginning of the twentieth century when building with steel and glass was discovered by High Modernism. How will that evolve over the long term? How long will this boom last, in your view?

KS: I believe for a long time—unfortunately and thank God. Unfortunately, because wood is truly an appropriate material in the present time of climate crisis into which we are sliding or maybe in which we already find ourselves. This climate crisis is no hype; it’s not a trend that will end in ten or fifteen years. Rather, it is a new reality that we will have to confront in the future.

But, thank God, wood is a good material. It’s not only able to store CO2 but also offers very many possibilities in terms of construction technology. For that reason, I believe, and we at Blumer Lehmann firmly believe, that building with wood is not just a brief trend, a hype that you chase and then abandon. I believe that this material already plays a big role in architecture and will play an even greater role in the future.

GAM: What do you recommend to architects about building with wood?

KS: I would recommend that young architects visit a timber construction company during their studies or, even better, do an internship with a timber construction company. If I could do my studies over again, I believe I probably wouldn’t have done an internship in an architectural firm but rather at a timber construction company. I believe that’s an incredibly valuable experience for a young architect.

GAM: Thank you for the interview!

Translation: Steven Lindberg